Hydrogen–Natural Gas Blending on LB NG 2-Stroke Engine

CFD plus engine test campaign with an OEM pre-chamber to map ignition behavior, stability, and emissions across blend ratios.

Project quick facts

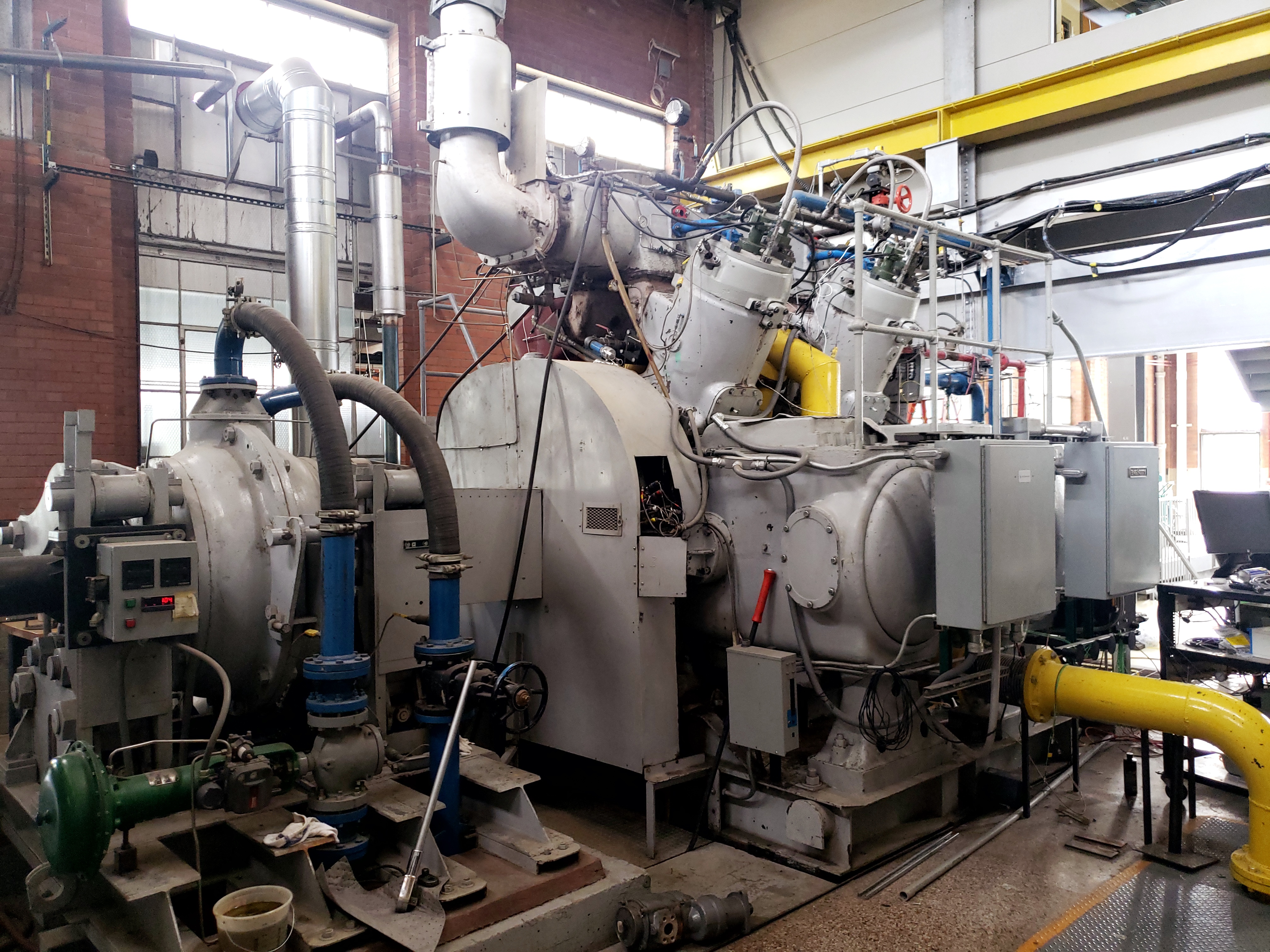

Engine platform

Cooper Bessemer GMV-4TF Large-bore NG • OEM Active PCC

Blend range

H₂ vol.%: 0-40 in MCC, 0-100 in PCC

Methods

CFD + Lab Validation

Outcomes

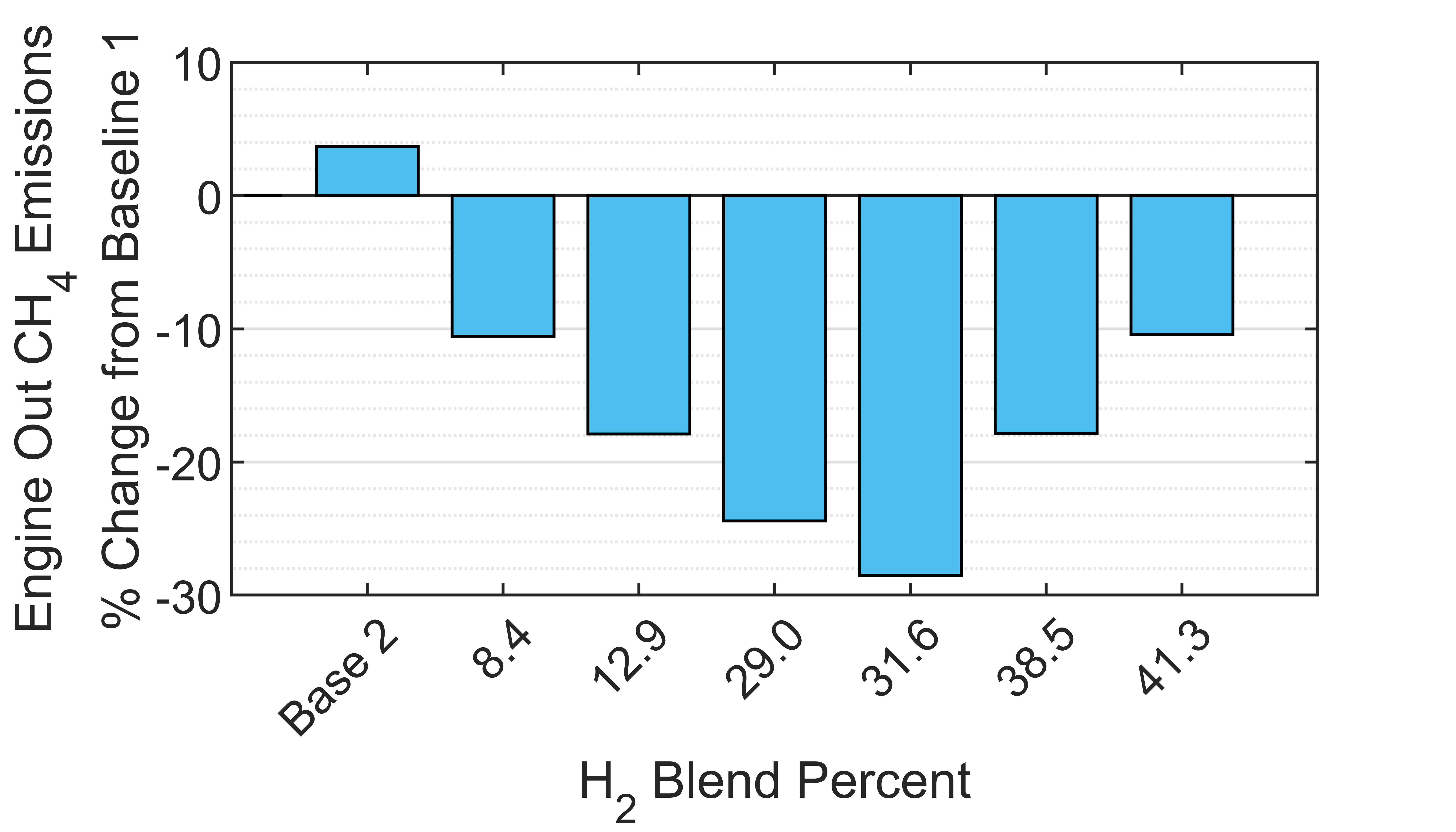

Decrease in methane slip, Decrease in COV's, Increase in NOx

Overview

Problem

With upcoming and ongoing restricting regulations to methane emissions from large bore engines, understanding how using hydrogen as a fuel supply will alter performace is paramount.

Objective

Quantify how incremental H₂ blend ratios affect ignition/stability/emissions with a stock pre-chamber.

Approach

CFD setup

- Convergent Science CONVERGE

- RANS, k-ε turbulence

- SAGE combustion

- Proprietary chemical mechanism

- Spark model with plasma kernel

Experimental campaign

- Engine configurations

- High pressure fuel injection (HPFI)

- Fuel PCC only

- Fuel MCC + PCC

- Mechanical gas actuated valves (MGAV)

- Fuel MCC only (no PCC used in MGAV)

- 0-41 %vol H₂ in MCC

- 0-100 %vol H₂ in PCC

- Incrementally increase the amount of H₂ blended into the MCC and PCC fuel lines and stabalize engine using COV of peak pressure

- PCC and MCC fuels are blended separately but in approximately the same %vol

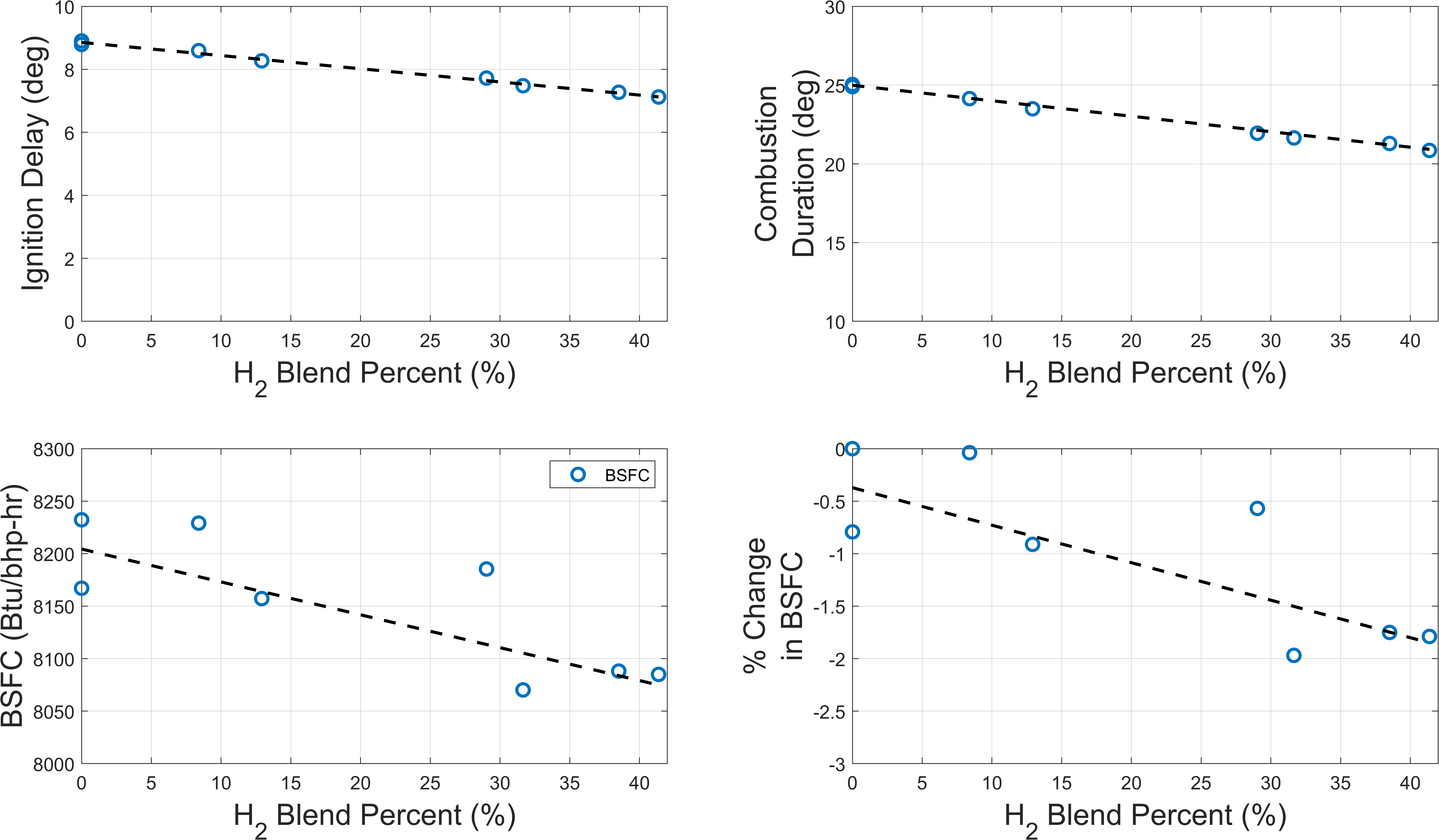

Results & highlights as H₂ blend increases (from experimental MCC/PCC only)

Ignition behavior

- Ignition delay decreases

- Combustion duration decreases

- BSFC decreases

- HRR advances

- Methane slip decreases

- NOx increases

- CO decreases

- UHC increases

- Combustion duration decreases with increasing H₂ blend

- HRR profile advances as H₂ blend increases

- COV's decrease

CFD ongoing